Updates from Bob, 2021 Q2

Use Loc-Tite for Preliminary Fit of Aileron and Flap Hinge Rod Ends

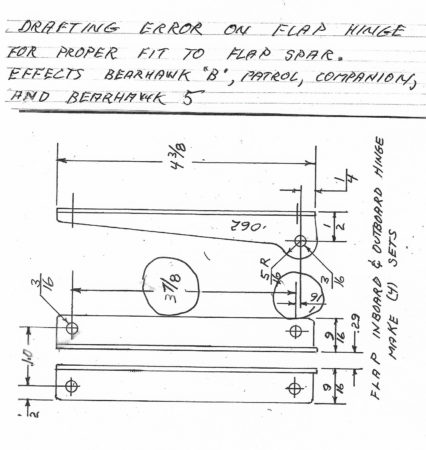

Flap Hinge Mounts: Tack Weld At First

Source: 1999 Beartracks, Bob Barrows

Refer to drawing #13. When making the flap hinge mounts it is best to just tack weld the pieces together first and not finish weld until the wing is finished and the flaps are in place. This will allow you to cut the tack welds and realign the hinge mounts if needed in order to achieve the best fit up between the flaps and wing. Once the fits are established then remove the fittings from the wing and finish welding.

Flap hinge mount as removed from welding jig, tack welded together only!