Summer 2023 Update: Do not operate these cylinders if you are running two pairs (pilot and copilot, etc). More information: https://bearhawkforums.com/forum/safety/84366-safety-update-regarding-bob-s-brake-master-cylinders-in-dual-brake-applications

Source: 2022 Q1 Beartracks

For years, Bearhawk builders used long-shaft Gerdes master cylinders (A-110-10). They were abundant and relatively cheap. Then when those got scarce around 2006 or so, folks started using a short shaft version (A-110-4), with a longer machined fork threaded onto the end. The top end forks are a special Bearhawk part that Mark keeps in stock.

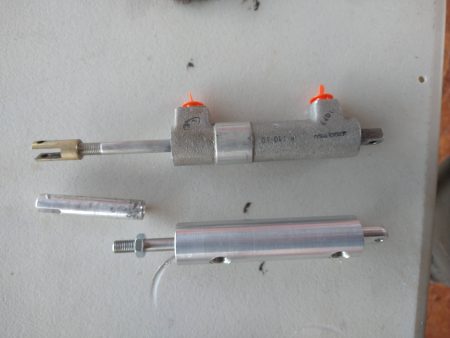

Lately, even the shorter shaft Gerdes cylinders have been harder to get. Grove and Matco have cylinders in the homebuilt price range, though they are still almost double the Gerdes price. The Grove and Matco cylinders use internal valves, but Bob had some ideas from his days as a pneumatic engineer for how to make the cylinders work with o-rings only, and no valves. The result is this new alternative.

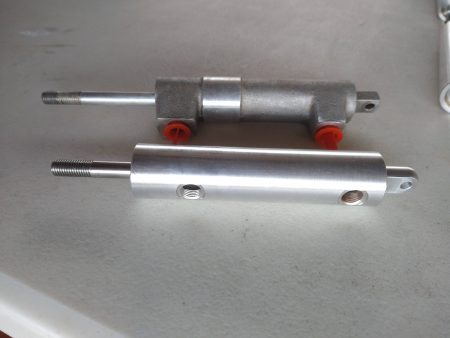

Notice that the new cylinders are machined aluminum, vs the Gerdes which were cast. Either gets the job done, but the new ones sure are pretty. The center shaft on the Gerdes is made from a very soft aluminum that is easy to bend while handling. On our blue Bearhawk I had to straighten a bent one, and one of the cylinders I removed from our new-to-us 303AP was also very bent. These new cylinders use a stainless steel center shaft which is much more durable.

Like the Gerdes, the new cylinder ports use 1/8 NPT pipe thread, which allows for installation of an AN822-4D (90-degree), AN823-4D (45-degree), or AN816 (straight) fittings to connect to hoses. Also like the Gerdes, the threads on the shaft are 5/16x24 (fine thread) which means it's easy to find jam nuts made from aluminum, cad-plated steel, or stainless as you prefer. Bearhawk Aircraft has the machined forks that go on the end. Both the forks and the cylinders have 3/16" holes for bolts or clevis pins, where the cylinders attach to the airframe and the forks attach to the brake pedals.

If you replace a short-shaft Gerdes cylinder with one of the new ones, Bob's design will be a drop-in replacement. If you'll be replacing the older long-shaft cylinders, you'll also need a set of the longer forks but can reuse your old jam nut. Bob prefers aluminum nuts, because, as you would expect, they are lighter. They are serving a very minor strength role here, and primarily just keep the shaft from rotating and to keep the threads from wearing. The top cap is retained by a snap ring, so like the Gerdes, these are field-rebuildable with off-the-shelf o-rings.

There is an important bit of guidance if you’ll be taking apart the cylinders. The inside of the threads near the top port are sharp, and can damage the o-rings during assembly or disassembly. Save one of the orange plastic plugs that ship with the cylinders, or procure

something similar. Before removing the top cap, insert the plug into the top port and press inward sufficiently to relieve the o-ring from being damaged on the sharp edge as the o-ring passes by the port.

If you are interested in a set, send an email to Mark Goldberg at Bearhawk Aircraft. Initial pricing is $165 per pair. The first batch of 100 has been distributed and the next batch is already in production.

You are not yet authorized to view this page. Learn more here.