Source: 2024 Q3 Beartracks, George Huntington

Back in 2006 I got the bug to build an airplane. Fully understanding it was a big project, but I put it on my bucket list anyway. Long story short, I persevered and 16 years later I was flying my hand crafted Bearhawk.

Building the airplane was a major undertaking that took countless hours in the shop with unrelenting commitment on my part and support and understanding from my wife, family and friends.

The pinnacle of it all being able to fly “my own” airplane to Oshkosh. That is where the aviation community meet to display their planes and see what other enthusiasts have as well.

The trip was planned out and I was flying with two other local pilots in their planes and I had a co-pilot, with me. The trio, a Cessna 170, a Cessna 180 and my Bearhawk set out on July 24, and headed from St Andrews, Manitoba for Duluth, Minnesota where we would clear customs.

In the air, we trued out at about 137 MPH burning 40 ltr/hr (10.5 Us gal/hr) at 55% hp. The AWOS in DLH transmitted that it was VFR but when we contacted the tower, they were not VFR. This weather change put us in a holding pattern and we circled for about ½ hr. Since there was no good news in the short-term weather, we decided to head back north to Fort Francis to re-submit customs paperwork and get fuel. The first leg was 3.8 hours, and we were only about 200 miles from home.

We gained customs and landing approval then flew across the river to International Falls and cleared US customs. A nice short hop of .2 hrs. We then flew from International Falls to Wautoma with airtime of 3.0 hours, fueled up and waited till OSH was open for the evening incoming traffic. With the heavy traffic of people arriving and the onset of the evening rush, there were unexpected delays, and we were put into the arrivals circuit and ended up circling with the invasion for1.1 hours, after which we decided to fly back to Wautoma where we camped overnight.

Thursday morning we packed up camp and headed to Fisk arrival, weather was below limits for arrival, so we were once again in the holding pattern for about 2.1 hours. We were pleased to see the weather lift, and we were allowed to land. We got through the maze of taxiways and parked in the homebuilt camping area where we got registered and I submitted to have my Bearhawk judged.

Later that day a team of judges stopped to inspect my Bearhawk. I was riddled with anticipation as I opened the cowl to let them look inside the engine compartment and stood back as they did a thorough inspection of my plane. After about ½ hour of checking their paperwork and making notes they left with a “thank you” for the opportunity to look at my aircraft. Now I had some free time so I went on tour through the other EAA aircraft and displays.

I was checking out the center square displays when I got a phone call asking if I was willing to do an air-to-air photo shoot of course I said yes. A briefing was set up for Saturday morning at 10 am. This piqued my curiosity so that got me wondering what was up.

When we arrived at camp later that afternoon after the airshow, I see a white flag “AWARD WINNER” on my propeller. That was an amazing surprise. Along with the red flag was the qualification form that had 14 judge’s initials on it with 3 red dots, WOW! I had been been chosen for an award.

I called my buddy Bob Matarelli from Duluth who had helped me out along the way while I was building the airplane, and he had always given me encouragement and had forecast that “you’re going to get a Lindy”.

Saturday morning, I just got started checking out the warbirds and got another call to do an interview and static photo shoot at the airplane in 15 minutes. I scooted back to the Bearhawk and met the photographer who took a substantial number of detailed photos and the completed the interview. They were very interested in my plane but did not reveal any information about awards.

We completed the photo shoot and interview and then proceeded to the briefing for the air-to-air photo shoot. The action would take place on Sunday morning as we were departing OSH.

I attended the Award ceremonies with my travelling companions at the homebuilt building at 6:30 Saturday evening. They went through the Kit Outstanding Workmanship and Plans Outstanding Workmanship plagues then to the Kit Champions bronze Lindy then to Plans Built Champion Bronze Lindy, the second Name announced was George Huntington Bearhawk C-GSOI wow I won a Bronze Lindy Plans Built Champion.

In preparation for the Sunday morning departure and Air-to-air photo shoot, we packed up camp at 6:00 am and taxied to an open area just to the south of the button of Runway 27. There, still more photos were taken prior to the flight. We taxied to RNY 27 took off and went into a hold over the bridge at Winneconne, circled for about 15 minutes. Then the C-210 camera airplane flew up to us and took the lead. We circled to the left for a couple 360’s to get the sunshine in the right area, some straight and level, up and down and a banking roll away to the left then with a wave of our wings we continued on our way to Cloquet for our first stop on the way home with air time of 2.8 hrs.

The weather was not cooperating as a line of thunderstorms prevented us from leaving Cloquet on Sunday, so we spent a night at the terminal in Cloquet. Such a nice airport with fuel and bicycles to use to go into town if need be. With time on our hands, we were able to look at Tim Tollefson Rans homebuilt nearing completion. With the help of my friend Bob, we were able to organize hangarage with Mike Ray a fellow homebuilder to park the Bearhawk overnight.

The next morning, the weather was still below VFR so waited couple hours until it cleared enough to go North with flight time of 2.5 hours and clear Canadian customs at Piney/Pinecreek, an interesting little airport which is half on the US side and half on the Canadian side.

Next leg was 0.8 hours to Oak Hammock Airpark just north of Winnipeg. Total airtime 15.5 hrs.

In my opinion, Bob Barrows has designed an excellent aircraft. He supplied a great set of plans, and was willing to sit and talk with me about the aircraft build. The Bearhawk 4 place meets all my expectations and more.

Mark Goldberg provided a sounding board and shared his knowledge and support throughout our build.

Friends of mine, Cameron Lawrence and Ziggy Smolinski were my build partners, together we have built 4 Bearhawks, so far 2 flying next one to fly this fall.

Special thanks to Jim Gile for his experience and patience helping me fly to Oshkosh as he has done this trip about 10 times already and this is my first-time flying in.

Two of us went to Oshkosh and had a third passenger “Lindy” on the way home.

Source: 2024 Q3 Beartracks, Dan Dagasso

In 2017 or 2018 my wife commented that we needed a bigger travelling aircraft for the West coast and the Mountains of British Columbia. I had just finished two and a half years restoring my Pitts S1S, which involved many many late nights at the hangar during the work week and a lot of my weekends.

At the time I was flying my RV6A, which was a great speedy aircraft. My better half wanted to be able to haul both of us and two roadbikes, two mountainbikes and some camping gear for trips to the coast or down to Moab/Montana/Oregon/Alberta (Yes my wife is Awesome, No you cannot have her).

My choice was pretty simple once I read about the capabilities of the Bearhawk. The one problem was that my wife forbade me from taking on another project by myself right after finishing the Pitts. After doing some research I found out that Steve Busby of the Ottawa area had built a few Bearhawks and had worked closely with Mark Goldberg representing the Brand North of the Border. Steve was also involved in prototyping the model B wings on N303AP.

Steve Busby knew that Mark had the Kit that had been intended as the new Model B demo aircraft in Storage at Bob’s place in Virginia. Mark was and is an absolute gentleman and after he endorsed Steve’s skills and quality I contracted with Steve to construct the Kit that was stored at Bob’s. I was looking forward to being in the air with the Bearhawk by late 2020. Unfortunately in the summer of 2018 Steve had a terrible motorcycle accident and spent close to a year in the hospital. It truly was a miracle that he survived.

By this time I had sold my RV and was working with a local engine builder to source and rebuild an IO-540. Ken Vike of Vike Aeromotive built up another awesome engine for me, he built the 360 in my Pitts and it is a beast. Ken knew the intended mission for the plane and he talked me out of any electronic ignition or non-certified parts, as this plane will spend a lot of its life in remote parts of BC. We kept the compression ratio at 9.2 so that I could use mogas in a pinch if I was in a remote logging or fishing camp.

By 2020 Steve made the decision that he did not think that his recovery was going to allow him to finish the aircraft. He did recommend one of his good friends who had helped him on most of hos builds over the last 10 years. In June of 2020 the kit was moved into the shop of Dale Lamport in Perth Ontario. Dale is a retired AME/Flight Engineer/MDRA inspector. Over the next two and a half years Dale made steady progress and we spent a lot of time on the phone with quite a few trips back East to work out kinks that always crop up.

My local Avionics shop helped me design and draw out the electrical system and avionics. One of my local avionics techs flew out to Ontario and spent a week installing and testing the electrical system and installing the panel. Kaine and Rob at Inland Communication Services were amazing to deal with and continue to be so on a daily basis.

In the fall of 2023 I had the plane moved to St Thomas Ontario for paint with John Gordy. My daughter who helped me fly the plane back designed the scheme. John Gordy did an amazing job executing the paint. Final assembly was completed at Purple Hill Air at St Thomas Municipal Airport, by John Goris and his crew of Johnny and Ben who were so excited to work on the plane.

Paul Ragany an octogenarian was hired to do the flight testing. Paul has over 26,000 hours in everything from J3’s. TBM avengers, turbine Ag Cats, a bunch of Boeing products 737, 777, 747 etc. and he still flies crop dusters on a daily basis. He is a legend.

George Miller was the CFI who helped fly off the 25 hours and spent three days helping me transition into the aircraft. On the last day of my checkout George noted that the weather was turning really ugly with the winds at 25 knots gusting to 30 with variable wind directions and ceilings of 800 feet. I was expecting him to call it a day but he suggested we go work on the crosswind runway with the crosswind varying from 50 to 70 degrees off runway heading. That was some of the most challenging flying I have done. We had the main runway as a backup with the wind straight down the pipe. I was so grateful to George for doing his best to make sure I was ready for the trip home. He knew that my daughter had come out to copilot the plane back home 2000 miles through some potentially challenging weather.

My daughter Emily got her license when she was 18 in my RV, but she has little tailwheel time so we managed the trip home with her doing most of the cruise flight and radio management with myself taking care of flying takeoffs approaches and landings.

Now that we are home I have managed to take the rest of the family flying and the instigator of the project, my wife, is so very excited to travel as we intended with a lot of trips back and forth through the Rockies to see our daughters who are now living and going to school on the prairies. I am looking forward to becoming current with IFR flying again and travelling up and down the west coast.

This morning my wife woke up and said, “ so, when are we putting it on Floats?” She doesn’t know that I am going out this summer to look at another Pitts that was ground-looped 10 years ago, and needs to get back in the air. I have always wanted to build a set of Pitts wings.

I had hoped to bring the plane to Oshkosh this year but that will probably need to wait until next year. My thanks to the Bearhawk community and especially to Mark Goldberg. I know that Virgil will make something great even better.

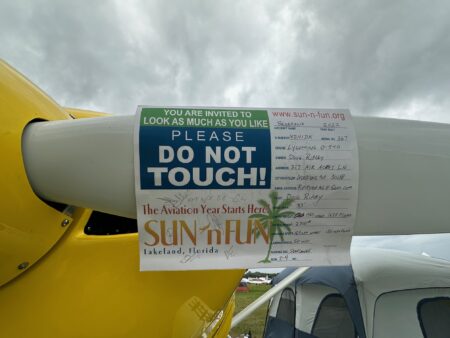

Doug Ripley with N241DK wins “Grand Champion – Seaplane” at Sun-N-Fun 2024! Thanks to Mike Swain for the photos.

Source: 2024 Q2 Beartracks

Based in Kamloops, British Columbia, Dan has completed his 8-year project and is out flying. We may have to wait until winter for him to be sitting still long enough to tell us more about his plane! He posted a few pictures on the forum and as you can see his paint job is stunning.

Source: 2024 Q2 Beartracks

Stenton Maddox First Flight in Texas – Bearhawk 4-Place – N628SD

Stenton’s plane has a carbureted O-540, a Dynon panel, and is covered in Oratex.

Source: 2024 Q2 Beartracks, Tyler Williams

“So, is there anywhere to go around here where you need a plane like that with those big tires?” This is the most common question I get from the classic plane peepers at the fuel pumps. And I don’t even have real Bushwheels yet. The Bearhawk draws a lot of attention. It is a cool looking airplane compared to the flock of sheep on the ramp. Just looking at it conjures up thoughts of adventures far and wide and nights spent under the stars. So, my response is always, “No. Not around here. But I didn’t spend two and a half years building a big, family hauling, off airport capable airplane to stay around here.” Here in the east, the mountains and ocean are several hundred miles apart. I love being in both places and the Bearhawk gives us more access to it all. I live in Charleston, SC, near the ocean and love it. Once in a blue moon, we get some good waves and there’s great salt marsh fishing to be had just a short walk down the street from our home. Charleston is also FULL of people and is lacking in wide open space to get away from it all. But, I can fire up the old Lycoming, load up the family and in an hour or two, we can be saddling up the mountain bikes, or pitching a tent in the grass.

The closest place we can fly into where the people are few and the stars are many is a little barrier island on the Georgia coastline called Creighton Island. It is a short 115 nm flight and though it is close to the mainland, being there feels far away. It isn’t “around here,” but is accessible for us on any good-weather Saturday. Flying along the coast at low altitude is always a treat. We follow miles of waterways, marshland and tidal creeks curling around the barrier islands that dot the entire Carolina and Georgia coast. We dodge pelicans and seagulls, spot dolphins and the occasional shark cruising the beaches. No magenta line is needed for a trip like this.

Creighton Island’s grass strip is supported by volunteers in the Recreational Aviation Foundation and all the info for visiting pilots is in the airfield guide on their website, www.theraf.org. The strip, lined with old growth oaks and palmetto trees, is a fun and fairly easy place to land, with a beautiful approach over the lowcountry marsh. Once in a while, a low pass or two is required to run the animals off the strip before landing. There are no roads out there and the island has been privately owned by one family for several generations. Over time they have made the place an easy place to camp. If you prefer a roof over your head, there are a few hunter’s cabins that have been built out there for the bow hunters who frequent the island for wild hogs. There is good well-water, a big cast-iron fire bowl, an outhouse, and even a weather station to check before you go. This isn’t the backcountry, but it is a beautiful quiet place to get the Bearhawk away from the pavement and spend some time outside with the family. Donkeys, pigs, cows, and armadillos roam free, making my 5 and 7 year old kids feel like they are on some kind of safari of the American South. Plus the fishing is great. Really great. The east side of the island has a little sand causeway out to a small sandy island on the waterway where bald eagles were nesting this past winter. On the other side, there are spartina grass flats that flood at high tide and offer access on foot to sight-fishing for spot tail bass. These fish are super tasty, fun to hunt and fight, and we are always hoping to score a few. If that’s not enough, there’s a boat dock where you can access some deeper water. It is hard to beat pitching a tent under the massive oak trees and Spanish moss, cooking dinner over the fire after a day of fishing, roaming the woods, and flying over a beautiful coastal landscape. It is almost close enough to home to consider it “around here” and we are thankful to have access to such a beautiful spot.

This would be a fun venue for a winter Bearhawk fly-in.

Source: 2024 Q2 Beartracks, Paul Minelga

Jared was nice enough to ask me to write an article about my first flight in the Bearhawk, and since then I have been thinking about what that actually meant for me…first flight in an aircraft that I had built. So, my take will be a bit different than what others have written.

I had a fascination with airplanes as long as I can remember, but my desire to build an airplane started in the early 70s while attending high school in Lacey, Washington. I was 17, worked at an Olympia airport FBO and was on the way to earning my Private Pilot Certificate. A friend took me to Tenino to meet the Sorrell family and I saw a Hyperbipe for the first time. Little did I know that it was the first one made and in my eyes it was really strange, almost scary-looking compared to the Cessna I had been flying. After watching a short demo flight, my friend took me over to meet another man on the same airstrip who was building a Stolp Starduster Too in his garage. All I remember was this guy in the middle of a really, really cool workshop with a tube fuselage under construction and surrounded by lots of aviation-related organized chaos. I was astonished that this guy was actually making an airplane…from plans…by himself! Then and there I decided that I wanted to, somehow, someday, do the same.

Fast forward to the mid 80s. I had left Army Aviation in Germany to start another career in the FAA as a center controller in Alaska. I had since married a wonderful German lady and had a son, and soon had another son. We were pretty poor at the time, and as a single income household on a trainee salary in Alaska, money was tight. I didn’t fly privately, but I dreamt of building a Van’s RV-6 and built R/C airplanes as time and budget permitted.

Jumping in time again to 2003, I was well-entrenched in the FAA. I had built my own home, my oldest son was in college having graduated high school in 2001 and son #2 was a junior. By that time I had realized an RV-6 wasn’t the right aircraft for Alaska and nothing else in the homebuilt world looked like what I was envisioning. A good friend of mine named Rob Taylor showed me a picture of a Bearhawk. I immediately said: “THAT’S IT!…ummm…what is it?” That Christmas 2003, Santa (with a little help from Rob) gifted me Bearhawk plans #708 and that’s when the journey started in earnest. Rob and I went to OSH 2005 and had a blast. That’s when I met Budd Davisson and Mark Goldberg for the first time at the Bearhawk booth. Also, I got my first ride in Mark’s (now Jared’s) N303AP and my first taste of what a Bearhawk was like. Not long after I ordered a set of “quickbuild” wings, all the tubing and flat stock to make the fuselage, and started building a shop to put it all in.

This is my first kitlog entry. Notice the OCD force was very strong:

Date: 3-14-2008

Number of Hours: 1.00

Brief Description: First Longeron

I started by laying out the bottom of the fuselage on the jig table. All went well except I found that Station C “pinched in” about 1/8th inch on either side when a line was drawn between Station B and D. Apparently, this should be a straight line. I triple-checked my measurements and found them to be correct. I polled the BH group about this and the answer I got was that it should be a straight line. It makes sense that way anyway. I’m trying to be too exact in my measurements it seems. I guess officially, this is the first day of construction although I never got the longeron bent the whole way. I’m sure when it’s all said and done that I’ll look back on this first log entry and just laugh!

This is my last kitlog entry after 16 years and 4269.2 hours, interspersed with weddings, memorial services, births, career changes, camping trips, and just living life:

Date: 4-26-2024

Number of Hours: 40.00

Brief Description: The end of my Kitlog

Well, this is it. The fairings and panels are all on and the project is complete. I put 40 hours of work on this entry because it spans the many days of the last two weeks that wasn’t logged, getting everything done in preparation for the DAR visit and reassembling everything afterwards. I taxied the airplane today and it’s ready for its first flight. That will happen when I get some refresher training. If you are reading this and building a project…keep at it. It’s not an easy thing to do. But if you do a little every day, it will eventually come together. Good luck!

I have to admit the first flight was a bit stressful. The tach had failed on runup, but it’s not required equipment. I had flown enough to judge RPM, but it did make me think twice and I almost taxied back. I lined up on the runway, but before I put the throttle in I paused a bit as per Ken Frahm’s (AKKen) suggestion. I went over everything in my mind again: I’m in an airplane that has never been in the air and I’ll be flying it at the waaaay upper end of its design speed envelope because the engine is brand new and needs to be run at 75% power or more to be broken in. Will the airplane fall apart? Probably not. I did the best I could and I know everything is right. Am I ready to land it if it make it that far? Yes. I can get it on the ground safely, it may not be elegant, but I’ll survive. A short prayer as the throttle went forward and the rest is, as we say, history. So it really wasn’t a first flight, but the culmination of a life ambition with the help and support of many good friends and family.

The Bearhawk performed very well and others before me have captured that in their first flight reports, so no need to rehash that. But here is a parting thought as I wrap this up. There are many nights I struggled in the shop making parts, remaking parts, correcting mistakes, making new mistakes, correcting those…on and on and on. There were times I just wanted to pack the whole thing up, drive it to a cliff overlooking Cook Inlet and dump it all in. Don’t give up. If you need to, take a short break, but don’t give up. Most times a good night’s sleep did the trick on helping solve a construction impasse.

If you want some inspiration, get this book and read it. It was gifted to me by my oldest son and it is a good read: The Propeller under the Bed: A Personal History of Homebuilt Aircraft by Eileen A. Bjorkman. On July 25, 2010, Arnold Ebneter flew across the country in a plane he designed and built himself, setting an aviation world record for aircraft of its class. He was eighty-two at the time and the flight represented the culmination of a dream he’d cultivated since his childhood in the 1930s.

Source: 2024 Q1 Beartracks

Chuck has completed his airplane with a C85 that Bob Barrows built. It has an O-200 crankshaft, high compression pistons, a B&C lightweight starter and alternator. Cato prop, Vetterman exhaust. He says, “It’s a little on the chubby side at 820# empty weight.”

Source: 2024 Q1 Beartracks, Scott Hoover in Alaska

N316BH, serial number 1266, is a plans build 4-place original model with some B model upgrades. I purchased the plans and many of the materials from a local man in Alaska who decided to go another direction with his build. It was built with a fair number of parts purchased from Bearhawk Aircraft and the VR3 Engineering tubing kit. N316BH has the original wings and tailspring but I upgraded the horizontal stabilizer, the door formers, and I re-enforced and strengthened the aerodynamic gear shock-struts with an internal round tubing. A skylight was added and lowered to match the wing across the top. I also reinforced the frame and welded a float kit along with ski cable attachment points.

The interior is simple and light with painted fabric. I kept my panel simple as well. I went with the MGL Xtreme EFIS and EMS along with a panel mounted iPad mini and two AHRS units that provide ADSB and air data to the iPad. All said and done I was pleased with my empty weight and CG. With the Bob Barrows O-540 and a metal two blade 84″ Hartzell propeller installed the empty weight came in at 1420 lbs. The CG is just aft of the forward limit with a pilot in the seat and empty fuel tanks. This leaves the entire CG envelope available for cargo, fuel and passengers. Impressive design for sure! My initial impression after just a few flights is WOW!!! What an incredible airplane! Very few things in life can beat that first flight! This was my first build and my first flight in a Bearhawk. After a couple of engine runs per the Lycoming instructions and a couple of taxi tests I was ready for the big event! After one more detailed inspection and one final run up I lined up on runway 20R at the Birchwood airport in Chugiak Alaska. It was a perfect day: 28 degrees, clear skies and little to no surface wind. The pressure altitude was well below sea level so I suspected great performance. Once on the runway I pushed the power up to 1200 RPM and let the plane slowly accelerate while taking one more concentrated look at the EMS, satisfied, I pushed the throttle on the untethered engine up to full power for the first time. She roared to life! I was thrown back in my seat with far more pressure than I have ever felt before in a single engine piston aircraft, it was at that moment that the smile came on my face and lasted for the next hour. The plane literally leapt off the runway before I even got the throttle to it’s stop. To my relief the airplane felt perfectly rigged and I rocketed to 3000′ at my planned 100mph climb speed. The first flight was all about engine break in and basic controllability checks. Fortunately, there are no issues other than some avionics problems that I’m still working through.

My overall impression of the Bearhawk is that it is perfectly designed for mechanically inclined individuals to build, even from scratch, with little experience in building aircraft. The great majority of the airplane is constructed using very basic metal working skills. The project took me nearly 7 years to “complete” as a hobby with many distractions along the way.

The plane feels light and even sporty in the air. It is wonderfully powered with an 0-540 and stable at high and low speeds yet still extremely responsive to flight control inputs. I look forward to exploring the entire flight envelope as I work through my flight test profile.