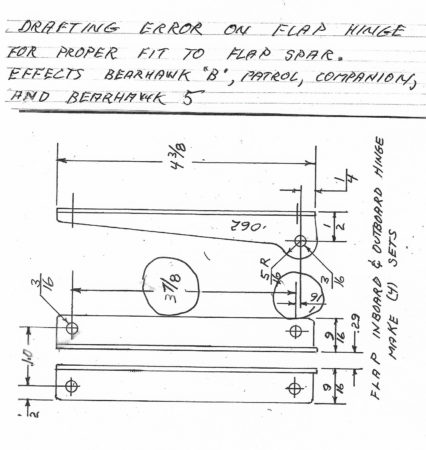

There have been two recent safety updates. The first was a minor drafting error in the flap hinge, which impacted the Model B 4-Place, Patrol, Companion and Five, and was distributed in April. This photo shows the revision:

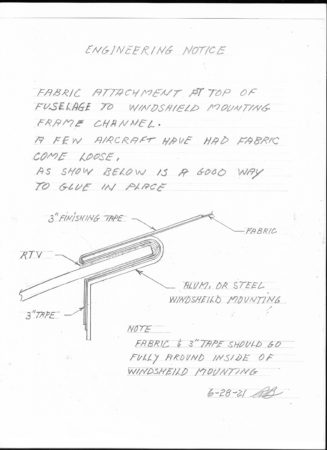

There is also a new update released 6/28/2021, which will also show up at bearhawksafety.com in the coming days. This is an Engineering Change that relates to the way the covering is tucked into the channel at the top of the windshield.

Bob’s instructions are, “Fabric attachment at top of fuselage to windshield mounting frame channel- A few aircraft have had fabric come loose. As shown is a good way to glue in place.”

There is also a new update released 6/28/2021, which will also show up at bearhawksafety.com in the coming days. This is an Engineering Change that relates to the way the covering is tucked into the channel at the top of the windshield.

Bob’s instructions are, “Fabric attachment at top of fuselage to windshield mounting frame channel- A few aircraft have had fabric come loose. As shown is a good way to glue in place.”

If your fuselage is already covered and isn’t routed as shown in the update, he says, “If it has been flying for a while, it should be fine, but it is something that we need to let people know about.” Bob also brings up the point that it’s crucial to follow the instructions of the covering system that the builder selects. Popular systems including Polyfiber, Stewarts, and Oratex vary greatly with crucial details. In a recent case, reinforcing tapes were able to peel up with fingernail intervention, which prompts Bob to bring up that point.

Bob and Mike have been busy building engines, trying to reduce the lead time which has grown long due to strong demand.

His Bearhawk LSA is back to flying status, thanks to builder Collin Campbell in Missouri. Bob flew the airplane home and was pleased to report it flies straight after the extensive rebuild. Some of the original engine parts fly again in the new plane.

If your fuselage is already covered and isn’t routed as shown in the update, he says, “If it has been flying for a while, it should be fine, but it is something that we need to let people know about.” Bob also brings up the point that it’s crucial to follow the instructions of the covering system that the builder selects. Popular systems including Polyfiber, Stewarts, and Oratex vary greatly with crucial details. In a recent case, reinforcing tapes were able to peel up with fingernail intervention, which prompts Bob to bring up that point.

Bob and Mike have been busy building engines, trying to reduce the lead time which has grown long due to strong demand.

His Bearhawk LSA is back to flying status, thanks to builder Collin Campbell in Missouri. Bob flew the airplane home and was pleased to report it flies straight after the extensive rebuild. Some of the original engine parts fly again in the new plane.