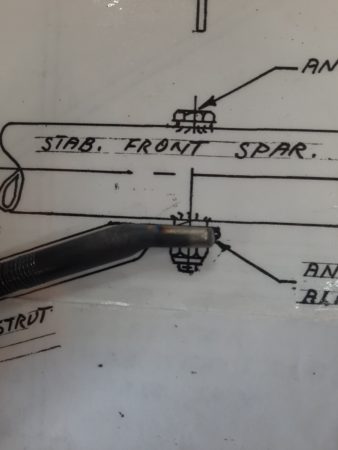

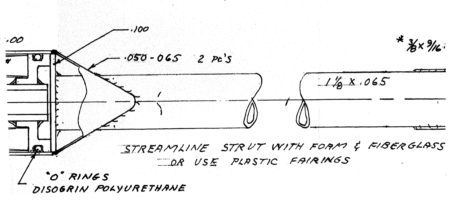

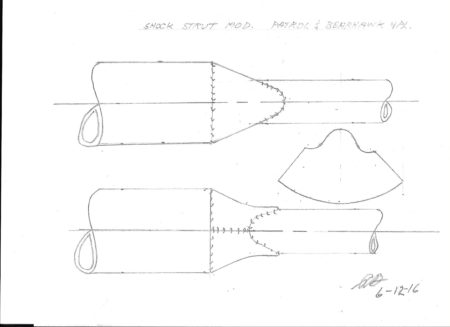

Bearhawk Aircraft Service Notification June 16, 2020 – For questions call Mark Goldberg, 512-626-7886 The horizontal stab strut for the Patrol and LSA share a common design feature on the top – how they are attached to the leading edge tube of the horizontal stab. An AN5 bolt has its head removed, and it is heated and forged flat with the 3/16” hole drilled for attaching to the horizontal stab with an AN3 bolt. The factory also cuts some more threads to add additional adjustment length. Some of these parts have left the factory improperly forged. The forged part (where the 3/16” hole is) needs to be flat so it fits flat against the bottom of the horizontal stab tube and also have the nut on the bottom fit flat. The parts not forged properly have an angle to them and are not flat on both sides. This can put stress on the AN3 bolt. There are two ways to fix this part if you have one or two that are not forged flat. One side can be ground down flat on a bench grinder if the remaining material is at least 1/8” thick. Of course any roughness or marks from the grinding would need to be polished/sanded out. Bob Barrows does a different fix for a situation like this that requires welding. A washer is tack welded to the “fatter” side of this part where the attach hole is. Then the other side of this washer is adjusted so it is flat compared to the other side. Then finish welded in place. Please inspect these parts that came with your Patrol or LSA kit. If they have this problem you should try to make the “repair” as detailed above. If you are unhappy with the result for any reason, let us know and we will replace these for you.