Duplicating Fitted Tube Ends with Paper Templates

Weight Savings with Composite Floorboards and Door Skins

Thermoforming a Custom Skylight

Carbon Fiber Door Construction Using 3D-Printed Joints

Winter 2024 Update from Bob Barrows – Companion Progress

Source: 2024Q4 Beartracks

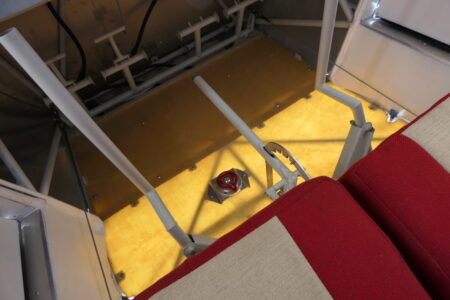

Bob’s Bearhawk Companion is looking more and more like an airplane. During our October visit, the weight was 1010 pounds, as pictured. In November, Bob broke some bones in his foot, and that has limited his shop hours. Thankfully the cast was removed a few days ago and in the coming weeks he can rebuild strength and spend more time in the shop. He is currently working on the exhaust and baffling. I asked whether he used a kit for baffling, and he said no. He enjoys the challenge of making a custom baffling set for each installation, and is also somewhat particular about how he wants it to turn out. He says, “When you already have an airplane to fly, it doesn’t matter that it takes a little longer.” He enjoys building things and likes the rewarding feedback that comes from consistent input to a project. There is fun and a sense of accomplishment in seeing it come together. The new Companion has several interesting features including Kevlar composite floorboards. Their translucence is displayed with the belly pan removed. The door skins are carbon fiber, and the mouse door hinge is a strip of Kevlar layup.

Summer 2024 Updates from Bob Barrows

Source: 2024 Q2 Beartracks

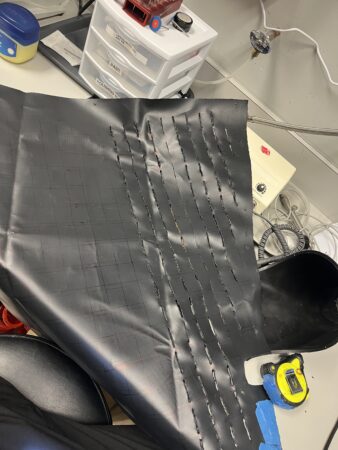

Work continues on Bob’s Companion project. As of press time he did a preliminary installation of the wings and has mostly completed the cowling. There is a mock-up engine that has no cylinders in place, and he has validated alignment and positioning of the engine, and is quite pleased with the kit’s conformation to the plans. The ailerons, flaps, rudder are covered, and the elevators and horizontal stabilizer are in progress. With the mock-up engine in place, the weight was 767 pounds. Bob feels like he is on track to meet the target empty weight of 1050 pounds. This build uses carbon fiber door panels instead of aluminum. Bob says it saves a little weight, and he’s pleased with how the carbon panels flex, drill, and otherwise behave much like aluminum would. To make them, he starts with a flat sheet of aluminum. He says you can also bend the aluminum if you want the part to also be bent. He applies lots of wax to the aluminum, draws out an outline of the rough shape of the panel, and paints resin onto the panel. Then he lays 2-3 layers of carbon onto the panel, and the next day, it’s ready for cutting to shape and installing. He made similar floor boards out of Kevlar, and figures those are 2/3 to 1/2 the weight of aluminum in the same application.

Bob and Diana recently flew the Patrol to Pence Springs, West Virginia for a get-together that included around 30 airplanes. They have a nice long grass strip there. Diana’s improved mobility and health are great news. She’s always eager to ride along whenever Bob flies. He says he alternates between flying his Patrol and LSA, just to keep both active, and enjoys both equally.

He has not been working much on his electric Ultralight project. It is still pending a new motor controller to up the motor output from 230 to 300 amps. Bob did design and build a new full-castering tailwheel for it, to improve taxi handling. The new tailwheel doesn’t attach to the rudder for steering but is easier to maneuver than the original skid. Bob says back when he flew his RV3 the tailwheel could either be swiveling or steerable, so he usually left the chains off and allowed it to swivel so that he could turn around more readily at the end of the runway.

Bob has been working on a solution for the Brake master cylinders that uses an EDM (electrical discharge machining) machine to make very precise fluid passageways inside of the bore. The EDM machine is well-suited for this kind of work and yields very smooth and precise shapes down inside the bore, based on the shape of a custom electrode.

Save the date for Bob’s Picnic on 10/19/2024 at VA04!

Cabin Organization with MOLLE

Source: 2024 Q2 Beartracks, Tyler Williams

I like clean organized spaces. Well, at least I do in my airplane and in my kitchen. My truck, on the other hand, is a complete mess…always. It looks like I live in it, which sometimes I do. But not a lot goes on inside the truck that forces me to be meticulous about it being clean and organized. I sit, hold the wheel, throw the snacks in the center console and turn on some good tunes. My kitchen is a different story. My chef’s knife is sharp, my spices are stocked and I am a stickler for “mis en place.” When everything is in its place, I can work efficiently and get into a flow to create, improvise and make great food.

Operating the airplane is a similar experience for me. I like everything in its place, the plane prepped and my mind sharp for the task at hand. Flying a plane, at least the way I do it, involves much more than road tripping in the truck. I don’t just get in, hold the wheel and follow the line on the map. From the preflight, to the engine management, to flying the terrain and improvising the route around weather and airspace, to chatting with ATC and jotting down instructions, there’s always something to do. An organized cockpit helps keep the mind free for the important things, and I don’t like anything flopping around loose. When flying far, I need water, a bag of snacks, sometimes a pen and paper, sometimes I need my flashlight, I’ve got my InReach on and I like to plug in my phone for music. I keep a lot of stuff in the back of the airplane too and it all needs a secure place to rest. From the basic things like a screwdriver, fuel tester and a small flashlight that get used every preflight, to the just-in-case tool kit, spare fasteners, tubes and patches, to control locks, tie downs, travel chocks and a first aid kit, I like to have what I need, when I need it. You can usually find help anywhere in the lower 48, but it sure is nice to have what you need to handle things, in flight and on the ground.

When I finished the Bearhawk and started venturing across state lines, I kept all the tool kits and spares in a duffel bag in the baggage area. But, digging through a bag of stuff to find what you can be annoying at best. For the cockpit items, I initially used the side pockets installed by my feet and the seat back pockets to stow checklists, small items, snacks and water bottles. But we travel as a family often and I like to keep those seat back pockets clear for my kids to stow their drawing paper, books, cards and such. My side pocket is best kept minimal so I can get my checklist or writing pad without fumbling around down there while trying to fly and my wife likes to have her side available for her magazine or book.

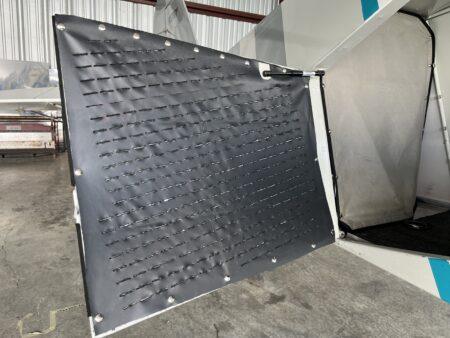

I got some inspiration from some nice overland camper trucks that used the MOLLE (Modular Lightweight Load-carrying Equipment) system to organize gear and tools. I saw seat-back MOLLE panels with small pouches and also some nice tailgate MOLLE panels for easy access to tools, even when the truck is loaded with gear. That seemed like the perfect solution for my plane. Our doors are all recessed slightly from the interior so there’s a little space there that can be used to hang a MOLLE panel and install some organizers.

I made mine out of PVC coated Cordura nylon. I found some basic dimensions for the standard laser-cut Molle grid, drew it out on the fabric and simply melted the slits with a soldering iron. Mine are 1.12” wide slits, spaced ¼” apart horizontally and 1” apart vertically. I probably don’t have the exact military spec, but it was easy to lay out and fits all the attachments well. Someone more digital savvy could do the layout on a computer and have the fabric laser cut for a faster and more precise, factory looking result. I installed snaps in the door frames and fabric and snapped on the panels. They are lightweight and work great. Up front, I have my water bottle holder, sunglasses, pen, charge cord pouch, a place to keep my phone and snacks and my fire extinguisher secured on the door for easy access and still have all the elbow room I need. The passenger door has a panel as well with the same drink holder and stuff pouches and my wife loves it. The big panel on the aft baggage door stores my first aid kit, gust locks, travel chocks, extra quart of oil and funnel, preflight tools, hanging luggage scale, spare fuel cap, pitot cover, etc. etc. You can certainly stuff all these things under the back seat and that works just fine. But it sure is nice when the plane is fully loaded to be able to just pop the baggage door open and grab what you need.

DIY Seat Upholstery

Source: 2024 Q1 Beartracks, Mark Richardson

Those of us who are building (or have built) an airplane know that there is a lot to learn over and above being a pilot. Leaving aside manual skills, we need to learn about the rules and regulations for building and licensing, avionics and electrical design, AC-43.13B contents and how to actually do … stuff … correctly, it’s the manual skills that are the bread and butter of aircraft building and the most fun.

With all models of the Bearhawk you need to learn how to rivet (both solid and pop), work metal (bending, forming, filing, etc), do fabric covering, run cables, install the engine, fit and prep fibreglass, cut, trim, and fit plexiglass, and a plethora of other detailed skills. If you are brave (stupid?) enough and decide to scratch build, you also need to learn to weld, operate metals shears and brakes, build and align jigs, and so on. There are lots and lots of jobs and skills you will learn by building an airplane.

A couple of the jobs that are often farmed out to the pros are aircraft painting and seat upholstery. I had already learned to paint an airplane when I built my RV-8 20 years ago (Google C-GURV) so although I am using a completely different paint process this time (Stewart vice Imron), it wasn’t totally new.

Which brings me to the purpose of this short article; how I upholstered my aircraft seats (your mileage may vary, batteries not included). I had considered (very seriously) just buying upholstered seats and carrying on. However, three things made me change my mind: 1) this would be a new skill that might be fun to learn, 2) I’m now retired so I have time, and 3) OMG it is expensive to have seats professionally done! I won’t lie, I found this the most challenging thing to learn yet. But it was actually fun and I am, well, not richer, but certainly not poorer by hundreds of dollars by doing it myself. I can’t give a step by step how-to with measurements and detailed instructions otherwise this article would be book length. However, I will show a bunch of pictures with descriptions of what is happening and notes on things to think about and avoid. Yes, even you can learn to do this.

The tools and materials:

We have a 60 year old Singer sewing machine that we bought fully restored a couple of years ago. No fancy computer features but it is indestructible and works great. You’ll need pinking shears for the fabric, regular scissors for the foam, sewing clips, rulers, marking pens, paper/cardboard for templates, tape, spray contact cement and a work surface. I used an electric carving knife to carve up the foam for the seat parts.

For the fabric I used RipStop because it is quite inexpensive, is super tough, it won’t give me third degree burns on a sunny day like leather, and actually looks really good. You’ll need some backing foam (1/2” or 1cm) that has a backing material on it, and foam for the seat bases and back. I got the Confor Foam seat bases from Aircraft Spruce for the front seat bases and used 2” firm upholstery foam for the rest.

The Method:

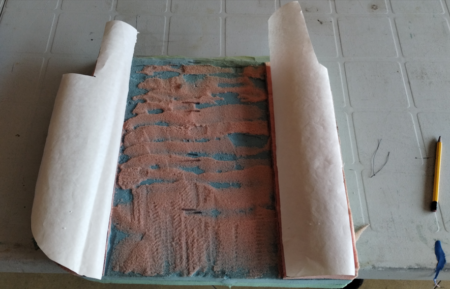

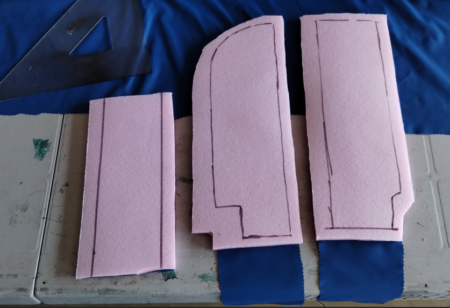

I made templates out of paper and cardboard for the various components of the seat cushions that were then used to cut out the fabric, backing foam, and to lay out the sewing lines. After a LOT of trial an error (mostly error), I added 3/4” on all sides to my fabric and backing foam patterns and just snipped off the excess at the end. Once the fabric pieces and backing foam were cut out, I used spray contact cement to apply the fabric to the foam (this is temporary to keep everything in place for initial sewing). I then used the paper template to mark on the back of the foam where I wanted to sew. Again, trial and error taught me to sew with the fabric side down as the feeder foot (or whatever it is called on the sewing machine) worked way better this way.

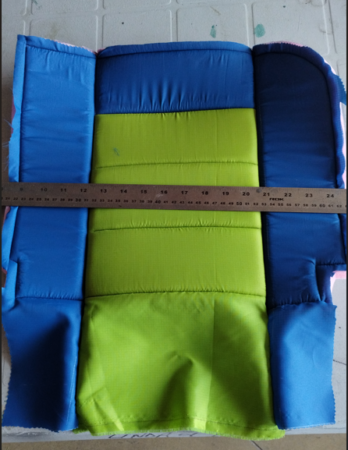

Once you get the various individual parts made you need to put them together. The trick is to overlay the existing sewn seams on the two sides such that when you sew the pieces together the seam disappears. Use LOTS of clamps. I put an extra 2” of material where the fabric would wrap around the back of the seat so there is material to pull on to tighten the fabric then staple. I used 1/4” birch ply with lightening holes as the backing material and stapled the fabric to the ply. The ply is quite light, and since the RipStop weighs almost nothing, the seats are not at all heavy. I will use Velcro to attach the seat components to the actual seat frames.

I realize this is hardly a “this is how to do it” article, but I hope it is an encouragement to try it yourself the next time you need seats for your airplane. The most expensive part of the whole thing were the Confor Foam seat bottoms ($200 CAN each!!). The rest was very inexpensive with the RipStop material < $5/running yard. Our own Michel Roy is the one who inspired me to do this with the seats he made for his Bearhawk using RipStop and between looking at his pictures and watching a BUNCH of YouTube videos, I was able to produce these: